Internet of Things Technology in the Manufacturing Industry

Surrounded by the vibrant growth of innovations and technology in the 21st century, the global economy is at the cross currents, from the Third Industry Revolution driven by digitalization and automation to a new era where business intelligence are more powerful than ever given trillions of sensors to revolutionize how we do businesses today. Being at the forefront to deploy technology to drive down costs and improve competitiveness – let aside whether the traditional economics models would sustain the assumptions in current global arena and years to come – manufacturing industry is competing fiercely in operational optimization, supply chain efficiency, and predictive maintenance, made possible by the advent of big data feedback, advanced analytics, predictive algorithms, and automatic systems, and therefore the Internet of Things (IoT) economy.

In this article, section I explains what is IoT and why manufacturing should get on board, from the perspectives of two megatrends of aging demographics and resource scarcity. Section II examines current applications and potential visions developed at two top industrial innovators, Saint-Gobain and Bosch, regarding factory digitalization, data-powered smart preventative maintenance, quicker response to market demands, inventory management, logistics and supply chain optimization. Section III elaborates on implications associated with IoT economy, including first, corporate C-suite commitment is needed to support the deployment of the technology, because challenges such as co-existence and interoperability need substantial investment and retrofitting; second, highly automated system enabled by IoT brings technological unemployment and potential severer job polarization; third, business models need to be constantly re-evaluated to capitalize the opportunities brought by IoT, including extreme productivity and transparent value chain. Section IV continues with concerns to data security and privacy – how to construct secure networks and how to ensure data responsibility and anonymization, and whether education system and financial support are in place to train the majority of necessary skills to avoid ending up with lower-level jobs as the computational age comes.

Section I The Era of Internet of Things

The history of mankind is a long-written episode driven by disruptive forces. The European feudal economy was disrupted by the onboard of the steam-powered mechanics, following with market structure and legal framework necessary to breed the well-beings. Yet soon after the Second Industrial Revolution marched into the era, epitomized by mass production together with mass carbon dioxide emissions, strengthening the economic power while threatening the prosperity of life on earth. As Jeremy Rifkin, the widely recognized scholars and social critics, proposed that “a bold new economic narrative” is needed to take us into a sustainable post-carbon future, while Internet of Things is one of the building blocks that precipitate the profound transformations (Rifkin, 2012).

Technically defined, Internet of Things is a system of interrelated computing devices, mechanical and digital machines, objects, animals or people that are provided with unique identifiers and the ability to transfer data over a network without requiring human-to-human or human-to-computer interaction (Rouse, 2019). In a broader context in regards to societal progression, by connecting of trillions of devises and transferring and communicating multiple data points, IoT provides a “distributed capitalism” and “democratized manufacturing,” terms coined by Rifkin, that any individual would participate in the peer-to-peer, distributive, and lateral networks, and that any business could utilize the instant feedback to gain visibility of current state and strategically swerve the wheel to the desired destination (Rifkin, 2012).

As an Operational Controller working for a global manufacturing firm, a consolidated vertically integrated conglomerate born and raised in the Second Industrial Revolution, I am deeply concerned that corporations, which fail to reckon the transformation – from rigid mass production with subtractive manufacturing processes and integrated vertical value chain, to a collaborative peer-to-peer distributive networks preconditioned by IoT and technological breakthroughs in the communication/energy/transportation matrix (Rifkin, 2015) – will lose their competitiveness overtime.

Furthermore, the witnessed megatrends – shifts in behavior or attitude that has global impact regardless of industries (Euromonitor, 2017) – of aging demographics and resource scarcity are both calling for corporate’s responses in shaping a sustainable and brighter future for decades to come. First of all, aging demographics has become the world-wide issue. The year 2030 is said to “mark an important demographic turning point in US history” according to the 2017 National Population Projections published by U.S. Census Bureau (2019). By the time, all baby boomers – the biggest population increase in the time of US history – approach retirement age, causing the national demographics to transition from pyramid to pillar, signaling the need for unprecedented productivity to for the labor force to support the entire population.

The picture does not variate a lot when extending to other countries. In Europe, the decrease in fertility and mortality rate, combined with a higher life expectancy, is projected to double the old-age dependency (the number of people 65 and over relative to those between 15 and 64) ratio to double to 54 percent, meaning that from four working age for every elderly citizen to only two (Carone & Costello, 2006). Another faster than ever aging population exists in China. The notorious one-child policy, deployed to control post-war population growth in 1979 while the government prepared the social welfare system, was replaced by two-children policy in 2015 to promote population growth (BBC, 2015). Such aging demographics results in shortage of labors while increases demands for goods and services. To manufacturing firms, higher productivity is required more than ever to support the societal needs, while the advent of IoT lays unlimited potentials to address such challenge. Appropriate strategy needs to be deployed today to harness the decreasing costs of infrastructure, pertaining to the communication, energy, and transportation networks.

The other megatrend to highlight is resource scarcity, in particular its relations to manufacturing industry. Whether you notice or not, the earth is already shifting beneath you, above you, and around you. Climate changes translate directly into impairment to global water ecology, food riots, and diminishing biodiversity. These by no means are irrelevant to modern day living. Take agriculture alone as an example. Based on a study conducted by PwC, the interconnectivity between climate change and resource scarcity could reduce agricultural productivity by up to one third in Africa in 60 years while the aggregate demand is projected to increase 35% more food globally by the growing population (PricewaterhouseCoopers, n.d.). The current economic model is no longer sustainable, neither to supply needs of the population, nor to cope with the planet. Zoom in to the manufacturing world, traditional subtractive manufacturing process – taking raw materials in and “subtracting” non-value-added parts during each step of the production process – is not sustainable in the foreseeable future, simply due to no more resources available to be subtracted. The three-dimensional printing technology, on the other hand, is revolutionary due to its “additive” characteristics, that recyclable materials could be used to print layer by layer, essentially ensuring no waste in the process.

A Circular Economy for 3D Printed Plastics Starts with Material

The future state of economy will be circular to be sustainable – an alternative to traditional liner “make, use, dispose” economy by keeping resources in use as long as possible to extract the maximum value from the products. Furthermore, shareable commons will be the new norm. We have already witnessed the embryonic of the shareable commons – cars, bikes, expensive vacuum machines, quick turnover of baby clothes, just to name a few (Rifkin, 2015). As the boundary of consumers and producers continues to blur, mass production will also retire and hand the torch to the next comer. Sailing across the megatrends and marching towards the future, manufacturing firms have no choice but to embrace the reality as opportunity and proactively plan strategically to go with the flows. The first step is to harness the power of technology, enabling extreme productivity and unfold future potentials to address current challenges. Leaders in the transformation will help shape the future, while the late-comers will have to be left behind.

Section II Current Applications and Visions

Saint-Gobain

Founded in 1665 and headquartered in Paris, the French multinational corporation Saint-Gobain started out as the luxury mirror manufacturer in the old days, dominating the market and later extending to a variety of high-performance, construction, and other materials in the modern world (Laubier, 2015). Surviving for almost forty decades, the company apparently knows the drill of being agile, looking ahead, and strengthening competitiveness for years to come.

Observing the every-increasing connectivity and laterally enabled collaboration, Saint-Gobain adopted Adfors, a subsidiary to the group specializing in fiberglass-based reinforcement solutions, an artificial intelligence-based software to optimize its furnace operations at the Hodonice site in the Czech Republic (Industry 4.0, n.d.). Not only does the furnace capacity increase by 57%, the rebuilt to furnace is able to cut energy consumption by 18%, carbon dioxide emissions by 20%, plus an increased service life, thanks to instant visibility to real-time production performance monitoring, such as energy consumption, temperature control, automated alert systems, machine parts monitoring for preventative maintenance etc (Another development… Hodonice, 2020). Another application is partnering with Elmodis, an IoT enabled industrial innovator to monitor big machines such as pumps, fans, and conveyer systems by connecting hardware components with cloud-based software to build analytical diagnostics, with potentials to be integrated into existing company software for complete dashboard and solution (Biggs, 2017). With Elmodis, Saint-Gobain avoided significant costs related to time efficiency loss due to enhanced visual management, diagnostic data, development of algorithms that predict anomalies in machines, and decisions of investments (Testimonials, n.d.).

BOSCH

Digitalization also enables ultra-customization and personalization, to satisfy ever-changing current demands and create potential demands, thanks to IoT’s ability of connecting all components in the value chain. At the forefront of envisioning and trialling concepts of Industry 4.0, the German multinational conglomerate Bosch deployed the Connected Industry business units within the Industrial Technology business sector, providing projects and solutions to internal and external customers to strengthen competitiveness and address sustainability (About us, n.d.). Their vision is that customizable products with fun-to-use three dimensional representations are provided at sales, allowing customers to tailor-build based on individual preferences. This is achievable because modularization of mechanical drawings and functionalities can be pre-discussed with engineering and production, while artificial intelligence can provide millions of variations to specifications, such as colours, sizes, and add-ons. Special requirements can also be configured instantly and preliminary drawings are examined by research and development to assess viability. After sales requests, configurations are instantly transmitted to engineering department for specs approval, production planning for optimizing capacity and ordering, and manufacturing lines for re-sequencing robotic combination and re-organizing work space to produce the desired product in an effective and efficient way. Each step requires fully integrated IoT networks. Collaborative feedback channels through all relevant participants in the progress, stimulating innovation and escalating efficiency. Real-time capacity utilization within multiple global manufacturing plants and various production key figures of actual performance also enable algorithms to level the supplies and reduce lead time. Higher level of automation, coupled with full-grade connectivity, offers complete transparency, reduced complexity, increased possibilities, and decreased business vulnerability as the uncertain future unfolds (Bosch Global, 2020).

Furthermore, Bosch is aiming to achieve a continuous digitized material flow, a new logistics solution for high transparency in the supply chain, enabled by IoT technology such as wireless sensors and gateways. Apart from traditional supply chain management in the manufacturing companies, where material flows are rather unpredictable especially if sourcing from great geographic distance with uncertain shipping conditions, Bosch’ Nexeed Track and Trace system takes advantages of unique identifiers and sensory technology, to pinpoint not only locations but also critical atmospheric information, such as temperature, vibration, and humidity etc. at regular intervals to the cloud-based database. Position can be precisely known on the world map and condition can be assessed before the shipments arrive on-site, therefore proactively managing supply chain and taking measures to mitigate risks of delayed or damaged products if necessary. Another application is “asset tracking,” that permanent trackers can be installed on load carriers, such as containers, trailers, etc. With such visibility, utilization ratio is visible and algorithms can be written to avoid inefficiency, saving losses not only on the balance sheet but more importantly to the environment and the society as a whole (Bosch Global, 2020).

Section III Challenges and Implications

Opportunities are inevitably accompanied by challenges along the way of marching into Industry 4.0. First and foremost, the corporate commitment to transform into the new manufacturing era needs complete top-down support for the fundamental leap forward. Especially for those conglomerates, which vertically consolidate the value chain to reap benefits in the previous industrial revolution, their transformation need much more efforts and commitments from the C-suite to further increase productivity and efficiency through smart and remote management across various facets of business operations. Some prominent challenges include co-existence and interoperability. IoT devices should “detect, classify, and mitigate external interference” as more coexisting devices will be deployed in close proximity in limited spectrum, and a fully functional digital ecosystem needs to be established to realize seamless data communication between devices, machines, and other physical, digital systems inside and outside own organization (Sisinni, Saifullah, Han, Jennehag, & Gidlund, 2018). To solve these critical issues requires costly research and development, retrofitting, or replacement to work with the latest technologies and upgrade current deployment for further growth potentials.

A hotly debated social implication is technological unemployment caused by the transformation to the new industrial era. According to the definition of Oxford Reference, technological unemployment refers to unemployment due to technical progress, which applies to particular types of worker whose skills are made redundant because of changes in methods of production, usually by substituting machines for their services (Black, Hashimzade, & Myles, 2012). As more cost-efficient production inputs become available to firms, the less competitive ones become obsolete. Put into the context of production. Technology performs consistently at a stable, higher level than human brains, which inevitably make cognitive errors consciously or unconsciously. Moreover, with initial investments and digital support, technology pays back within a period of time while workers are continuous cash outflows with complications to the society. As the costs of information, communication technology (ICT) and advanced algorithms decrease, repetitive works of data registrars, lower-grade administrative, and operative jobs, which do not contribute consultatively and optimize decisively, are to be replaced. So, an important question, as always, is what happens next? Where do those workers go? Will they move up into more intellectually challenging jobs as technology frees up their hands? Or will they end up with nothing as current jobs are taken over? Here I would like to cite an interesting argument proposed by Loi, a researcher from Digital Initiative Department of University of Zurich, that while technologies complement high-level skills and substitute for middle-level ones, there is no guarantee that workers will end up to higher level of works as a result, regardless of overall unemployment rate. Observed job polarization is an occurring phenomenon that validates the argument (Loi, 2015). The most recent disruptive forces brought by IoT are expected be accompanied by the evolvement of job variety and allocation, while the crucial question to answer here is how to ensure that employees are rather relieved by removing their repetitive and none-to-less value added works, and that employees have the capacity of performing analysis, improving algorithms, and driving insights for managerial decisions, than being pushed to the lower spectrum of job variety. Hence whether an education system is established to train the current workforce and future workforce-to-be of equipping the necessary skills, and whether workers have motivations and financial means to support themselves to undertake the endeavour.

With the deployment of IoT technology in the manufacturing industry, not only do productivity and efficiency accelerate at an unprecedented rate, but the increasing transparency of the value chain require businesses to re-evaluate current ways of doing businesses. Looking at the bottom line, several questions pose here to evaluate capitalization of technology. First of all, is current business model still applicable to capture all opportunities? Should individual product sales still be the top line driver, or alternatives such as subscription and servitization deem more appropriate to reap the added value? Or, the answer lies somewhat in between the spectrum, a combination of both through contracting? Then how about expense controls? How will rigid manufacturing processes be digitalized to provide analytics, optimized to be more efficient and effective, and/or modularized to satisfy ever-changing customers demand? Finally, how will the value proposition adapt to accommodate unique profit creating opportunities as technology unfolds its potentials? Of course no shoes fit all, and corporations need to look at their own business processes to determine specific applications, but the current way of doing businesses needs to be constantly re-evaluated, as more understandings to the added value enabled by IoT. Some general guidelines of opportunities, provided by the findings from Porter and Heppelmann, put forth five means of value creation, which would translate into unique profit creating opportunities. The five means include shortening the product development cycles due to bypassing the pressure of new product introduction of smaller scale, new business models such as cloud-based models and servitization of products, supporting customer success of making suggestions based on specific customer usage, product as a part of broader system, and finally data analytics (2015). IoT technology can be tailored for different companies to devise unique value proposition, given much more data points to measure the exact profit drivers. Case studies conducted by Rymaszewska, Helo, & Gunasekaran highlight that a machinery company could monetize the service of operational supports and optimization by monthly subscription fees as operational data for original equipment manufacturer (OEM) are captured, reducing the manufacturing costs per unit and offering more competitive pricings. Utility provider could transfer the maintenance support service costs to be part of a larger service contract given detailed machine-level sensor data are obtained in the central database (2017).

Section IV Concerns

On the flip side of increasing productivity and efficiency through the employment of digitalized platform empowered by massive data point collected real-time with performance, data security and privacy are of the top concerns.

Data Security vs. Data Privacy

A study on the practicality of Industrial IoT points out several security properties to consider when designing the infrastructure, including tamper resistance against potential physical attacks, encrypted database for confidentiality, secured communication network among devices, efficient identification and authorization mechanisms, and robustness of IIoT portals (Sisinni et al., 2018). With response to provide a trusted IoT ecosystem, research and development is making breakthroughs daily. For example, cryptographic techniques could be used to replace a traditional centralized server which deems unable to perform arithmetic operations over encrypted data (Choo, Gritzalis, & Park, 2018). Resolving these legitimate security concerns provides the crucial threshold for trusted further communication, operations, and advanced analytics.

Data privacy is another prerequisite that raises concerns. As the concept of privacy is broad and diverse by various literature, there are threefold guarantees as generally agreed, including awareness of privacy risks from things and services, individual control over the collection and processing of information, and awareness and control of subsequent use and dissemination to any outside entity (Ziegeldorf, Morchon, & Wehrle, 2013). There are a lot of questions and implications for different parties here. Who has access to the database? Who has the right to use and disseminate data and analytics? Who is responsible for the database – manufacturers of machines, company who employs the machines, operators who use the machines, engineers who analyse and optimize, or the plant managers? Do we have a robust legal framework to hold those who are responsible accountable for the data usage? How is the data collected? Whether data anonymization is guaranteed through cryptographic protection and concealment of data relations? More considerations need to be addressed in the field for worry-free applications.

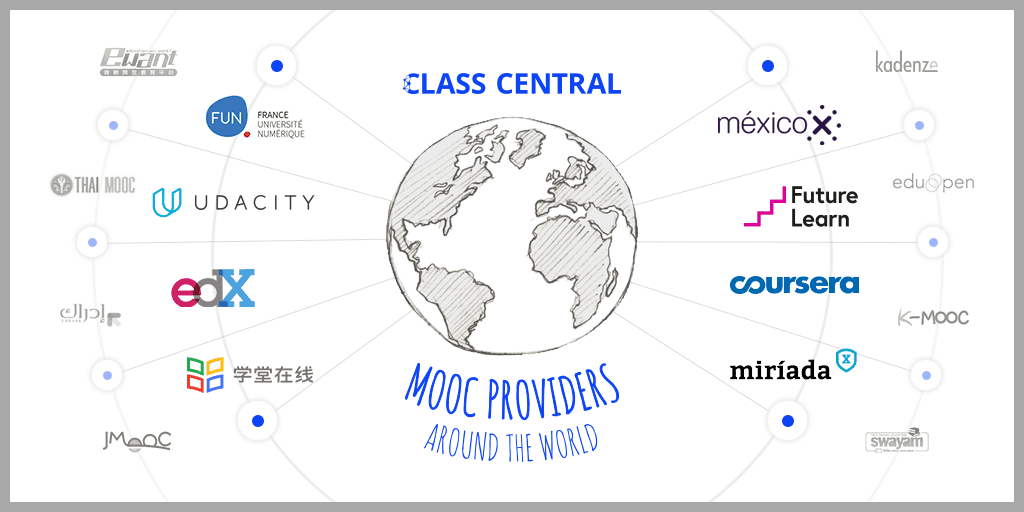

Another concern, as the response to technological unemployment as mentioned in the previous section, is whether the education system is established to train the necessary skills for jobs that require high-grade skills. Frey and Osborne’s empirical work by tracking the probability of computerization for 702 detailed occupations concludes that “about 47 percent of total US employment is at risk,” from industry such as service sector and logistics occupations, to production and general office and administrative support workers (2015). The surge of massive online open courses (MOOCS) and virtual academics, which is very cost competitive and mostly with great flexibility, allows students anywhere in the world to access lectures taught by prestigious professors at their own paces to ensure understandings and substantial learnings.

Anyone with learning spirits should be able to equip himself or herself with the skills required to transfer to a more intellectually interesting and experientially engaging job. At the same time, educational institutions should recognize the social needs and therefore adopt of business models to support massive online community as well as on campus experiences, avoiding “the monopolization of knowledge and privatization of higher education” (Peter, 2017). With that being said, whether workers at risk have the financial means to undertake the endeavour is another hurdle to self-improvement, which should be considered from the perspectives of government support, corporate sponsorship, and more.

References

About us. (n.d.). Retrieved from https://www.bosch-healthcare.com/en/about-us/

Another development project in Hodonice. (2020, January 22). Retrieved March 18, 2020, from https://www.vetrotextextiles.com/news/another-development-project-hodonice

BBC. (2015, October 29). China to end one-child policy and allow two. Retrieved March 16, 2020, from https://www.bbc.com/news/world-asia-34665539

Biggs, J. (2017, April 13). Elmodis raises a $4.9M round to find the soul of a new machine. Retrieved from https://techcrunch.com/2017/04/12/elmodis-raises-a-4-9m-round-to-find-the-soul-of-a-new-machine/

Black, J., Hashimzade, N., & Myles, G. (2012). Technological unemployment. A Dictionary of Economics, A Dictionary of Economics.

Bosch Global. (2020, March 18). Towards a Connected Industry with Bosch. Retrieved from https://www.bosch.com/products-and-services/connected-products-and-services/industry-4-0/

Bosch Global. (2020, March 18). When Freight Writes Its Own Log. Retrieved March 18, 2020, from https://www.bosch.com/stories/nexeed-track-and-trace/

Carone, G., & Costello, D. (2006, September). Finance and Development. Retrieved March 16, 2020, from https://www.imf.org/external/pubs/ft/fandd/2006/09/carone.htm

Euromonitor. (2017, September 7) The Importance of Megatrend Analysis. Retrieved from https://blog.euromonitor.com/video/the-importance-of-megatrend-analysis/

Choo, K., Gritzalis, S., & Park, J. (2018). Cryptographic Solutions for Industrial Internet-of-Things: Research Challenges and Opportunities. IEEE Transactions on Industrial Informatics, 14(8), 3567-3569.

Frey, C. B., & Osborne, M. (2015, February). Technology at Work: The Future of Innovation… | Oxford ... Retrieved March 24, 2020, from https://www.oxfordmartin.ox.ac.uk/publications/technology-at-work-the-future-of-innovation-and-employment/

Garrehy, P. (2015). The internet of things: Manufacturing's latest technology revolution. Manufacturing Business Technology, Retrieved from http://search.proquest.com.ezp-prod1.hul.harvard.edu/docview/1703667151?accountid=11311

Industry 4.0: people at the heart of the smart factory. (n.d.). Retrieved from https://www.saint-gobain.com/en/industry-40-people-heart-smart-factory

Laubier, M. de. (2015). Saint-Gobain 1665-2015: the history of the future. Paris: Albin Michel.

Loi, M. (2015). Technological unemployment and human disenhancement. Ethics and Information Technology, 17(3), 201-210. doi:http://dx.doi.org.ezp-prod1.hul.harvard.edu/10.1007/s10676-015-9375-8

Peters, M. A. (2017). TECHNOLOGICAL UNEMPLOYMENT: EDUCATING FOR THE FOURTH INDUSTRIAL REVOLUTION. Journal of Self-Governance and Management Economics, 5(1), 25-33. doi:http://dx.doi.org.ezp-prod1.hul.harvard.edu/10.22381/JSME5120172

Porter, M. E., & Heppelmann, J. E. (2016, February 12). How Smart, Connected Products Are Transforming Companies. Retrieved from https://hbr.org/2015/10/how-smart-connected-products-are-transforming-companies

PricewaterhouseCoopers. (n.d.). Megatrends Climate change and resource scarcity. Retrieved from https://www.pwc.co.uk/issues/megatrends/climate-change-and-resource-scarcity.html

Rifkin, J. (2012, March 3). The Third Industrial Revolution: How the Internet, Green ... Retrieved March 16, 2020, from https://worldfinancialreview.com/the-third-industrial-revolution-how-the-internet-green-electricity-and-3-d-printing-are-ushering-in-a-sustainable-era-of-distributed-capitalism/

Rifkin, J. (2015). Zero marginal cost society: the rise of the collaborative commons and the end of capitalism. New York, NY: Palgrave Macmillan.

Rouse, M. (2020, February 11). What is IoT (Internet of Things) and How Does it Work? Retrieved March 16, 2020, from https://internetofthingsagenda.techtarget.com/definition/Internet-of-Things-IoT

Rymaszewska, A., Helo, P., & Gunasekaran, A. (2017). IoT powered servitization of manufacturing – an exploratory case study. International Journal of Production Economics, 192, 92-105.

Sisinni, E., Saifullah, A., Han, S., Jennehag, U., & Gidlund, M. (2018). Industrial Internet of Things: Challenges, Opportunities, and Directions. IEEE Transactions on Industrial Informatics, 14(11), 4724-4734.

Testimonials. (n.d.). Retrieved March 18, 2020, from https://elmodis.com/en/client-testimonials/

US Census Bureau. (2019, October 10). Older People Projected to Outnumber Children. Retrieved March 16, 2020, from https://www.census.gov/newsroom/press-releases/2018/cb18-41-population-projections.html

Ziegeldorf, J. H., Morchon, O. G., & Wehrle, K. (2013). Privacy in the Internet of Things: threats and challenges. Security and Communication Networks, 7(12), 2728–2742. doi: 10.1002/sec.795